In our company, we even take into account the process of both ferrous and non-ferrous forging that involves the application of heat in metals like aluminum, brass, steel, copper etc. The metals are beaten up to take the desired shapes. Heat treatment equipment put in the metals like aluminum, steels, brass, and copper etc. These metals are usually taking the desired shape while heating treatment. Heat treatment is the oldest method of outside engineering. Heat treatments is an and mixture of process connecting heating at a particular rate, soaking at a high temperature for a period of time and cooling at various particular rate. Heat treatment equipments are been uses for the aircraft industry, automobile manufacturing, defence sectors, forging, foundry, heavy machinery and manufacturing, powder metal industries, steel industry, electronic industry, heat treatment equipment purpose is development in ductility, Relieving domestic stresses, Grain volume adjustment, Increase of power and resistance. It is the best for processing of a smallness thing mass-production article, and a hydrogen gas atmosphere maintenance heater is the use. Calculations of a stainless steel product, a copper alloy, a attractive material, and electronic products and measurement it can be use usually. It has had 30 kinds of normal machinery in stock for heat treatments of efficiency thing parts and small parts. Please decide with the reason of heat treatments, the excellence of the material, and a size. Heat treatment equipment manufacturers in Mumbai, India to all over the world since 1962 with ISO standards and specifications using high grade raw materials and durable quality components.

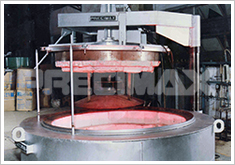

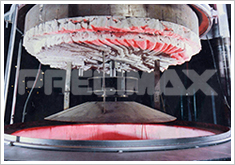

We have in store for our customers a wide array of Pit Type Furnaces which are manufactured using heat resistant stainless steel. The high grade of stainless steel helps the furnace to bear load and it also provides resistance to distortion. Safe operation, is an important aspect of this furnace because the fan and heating elements are separate from the load chamber. Due to this damage from accidental contact is eliminated. Metal lining is used in the entire work chamber which gives the furnace maximum durability.

These top loading furnaces are used for annealing, normalizing, tempering or for heat treatment in batch loads in a relatively small floor space. Up to 3 M in diameter, these units are available in temperature range from 250 degree Celsius to 1200 degree Celsius. These units can also be supplied with recirculation and atmosphere control, if required. Leading manufacturers of pit type furnaces as per the requirements with international standards and specifications.

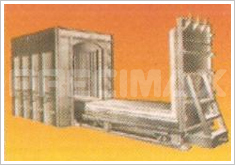

These furnaces are the most common of all types of furnaces and are used for stress-relieving, normalizing, homogenizing, and annealing. Sizes range from 1 m wide by 2 m long to 6 m wide by 20 m long. Electrical, gas or oil heated with a wide range of control / haulage drives! Configurations.

These vertical loading, horizontal traveling furnaces provide quiet movement for annealing, stress relieving, and other long and controlled cycles of heat treatment. These furnaces provide ease of operation with heavy loads, and are available in diameters of up to 3 m, power ratings up to 1000 kw and temperature up to 1000°c with atmosphere systems.

Modern Wire Galvanizing Lines are used for annealing, normalizing, tempering or for heat treatment in batch loads in a relatively small floor space. Up to 3 M in diameter, these units are available in temperature range from 250 degree Celsius to 1200 degree Celsius. These units can also be supplied with recirculation and atmosphere control, if required.

These on-the-site-built furnaces offer one-position loading and unloading and excellent temperature uniformity required in forgings or heat treatment. These furnaces are supplied complete with controls, drives rails, etc.

Car Tunnel Kilns

These kilns are designed for high volumes, and are built to handle heavy loads on continuous basis, and require minimum labor, have low operating cost and feature own recuperation system. Available in a wide range of sizes.

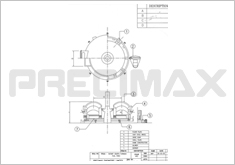

These equipment are built for drawing extra heavy wire rods

of 32 down to 10 mm. These equipments are ideal for drawing spring steel, pre-stressed concrete wire,

mild steel, etc.

These equipment are sturdy in built, and are driven by heavy

multi-stage horizontal gear-box coupled with control panel and motor. Diameter ranges from 800 to

1,000 mm. These blocks are available in the range from 30 to 150 hp, in various speeds, complete

with hydraulic pressure roller and heavy-duty die box.

These equipment is suitable for rod breakdown in rolled/annealed condition, and for inlets upto 12

mm. These are available in single or double deck configuration. These equipments are ideal for 8 mm

high carbon and 10 mm ms material downwards.

These equipments have Vertical drums

mounted directly on heavy-duty gear box in the size range of 300 to 450 pcd. Equipments can be

supplied with electricals, including motor and control panel. Normally certain range of speed change

through resistance is available.

These equipment are available in standard size range of 600, 400 and 300 mm, and can be

arranged individually or severally in tandem. These equipments are available for maximum inlet

of 8 mm high carbon steel. Minimum finish size recommended is 22 swg. These equipments are in use

at speeds from 2 to 12 mt/sec, and are very popular for high, medium and low carbon steels as

also stainless and alloy steel materials.

The construction of machine provides for a

vertical drum mounted on an integral gear box with extra features such as overhead take-off

automatic wire-break stoppage, protection for operator with wire mesh screens, inching, foot

switch, sequence contr6l and jerk -free start.

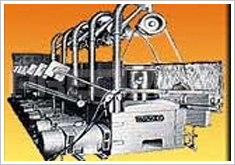

Stress-relieving, patenting, strand annealing, tinning or galvanizing lines for carbon steel. stainless steel, mild steel, etc. The system consists of multiple station arrangement, with coiling machines to move wire from station to station. These facilities can handle various processes and coating operations in a single line These furnaces are available in continuous lines up to forty heads operating simultaneously complete with pay-offs. cleaning range. guide rollers coiling machines, controls, etc.

These ovens, manufactured in collaboration with JLS Ovens Ltd. U.K. are individually designed to meet the clients specific requirements, relating to process fuel, method of work handling, production throughputs etc. The designs of these ovens include rugged construction, high safety features and other standard & unique features. These are available in a wide range of temperatures and sizes and come with optional features such as temperature recorders, programme controllers, timers, oven furniture etc.